Text: Juliane Gringer

Photos: BPW

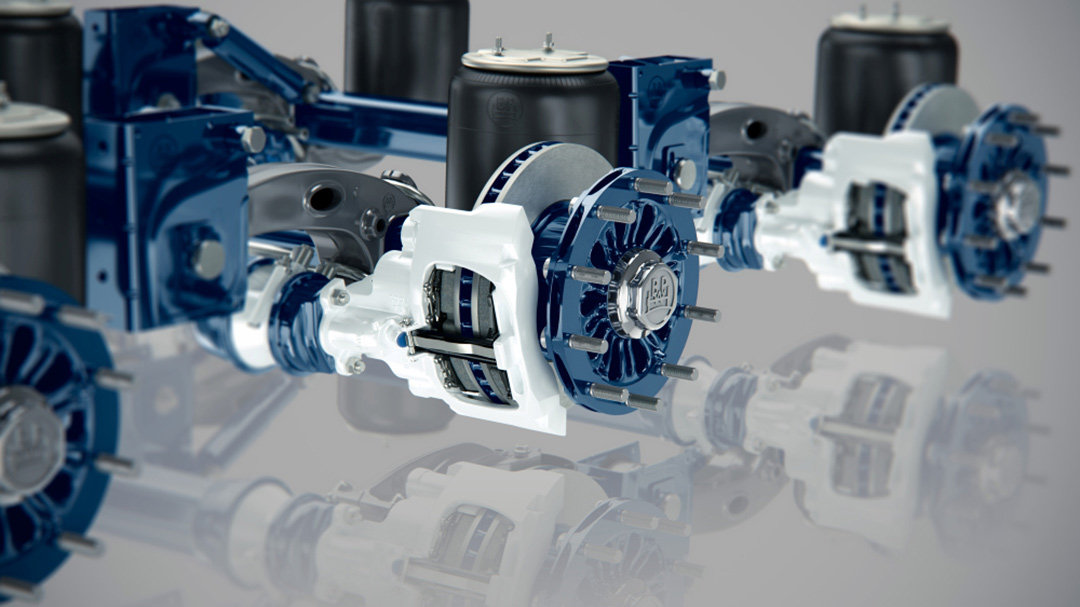

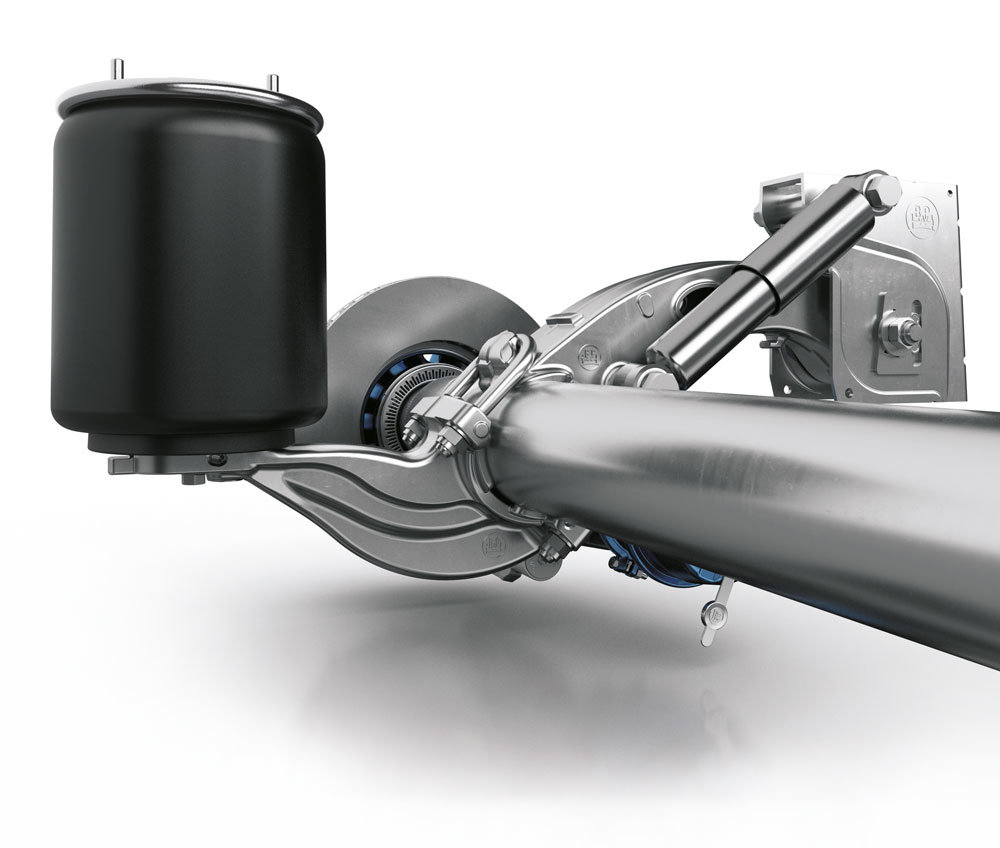

Thanks to the unique ‘digital DNA’ of all components, BPW is revolutionising how semi-trailer running gear is configured, ordered, produced, assembled and maintained. The digitalisation of all components and processes is making it much easier to find spare parts.

Simple online ordering for running gear

Right from the online ordering process for vehicle manufacturers in the BPW running gear configurator, it is clear that every component comes from a digital world. In the BPW portal, registered users can use intuitive selection fields to specify all of the parameters, such as for the brakes, ride heights, bellows and hanger bracket. The technology knows all of the potential combinations of parts and only offers those that are suitable in that particular case. This means that for the first time, running gear can be compiled in around five minutes. Real-time 3D visualisation provides a clear illustration of the configuration. Purchasers can also access the configuration to order the required components with just a few clicks and can even set a date if they want a delivery to be made later. The fully restructured process means a huge time saving for vehicle producers, as design and purchasing expertise can be efficiently combined.

‘BPW is using this simple application to make the ordering process for functional groups such as the running gear much quicker, less complicated and also less dependent on the expertise of individual employees,’ says Dr Dirk Nötzke, Head of Product Data Management at BPW. ‘We are thus significantly reducing the risk of incorrect orders and also enabling new employees to configure running gear more quickly.’ He says that the system will enable a totally new relationship between vehicle manufacturers and hauliers and will reduce the previous bureaucratic work to just a few mouse clicks, adding: ‘Selected BPW pilot customers have also made this possible through their in-depth involvement in the development process and by bringing their expertise to the project.’

Digitisation brings transparency

The fully digitised concept extends through the entire BPW production process: the data from the configurator is transferred directly into the company’s systems so that it is possible to trace which part belongs to which order at any time. The production process been adapted to modern Industry 4.0 standards – BPW uses networked, automated and therefore highly reliable production. Customers benefit greatly from each component being digitally recorded, as this means it is possible to track which parts have been installed in running gear throughout their service life. Every finished set of running gear is given a QR code, which garages can use to access all of the information relating to the components and to quickly and reliably find the appropriate spare parts if necessary.

BPW Aftermarket Group: identifying spare parts is a piece of cake with upLink

State-of-the-art manufacturing processes

Production partnership

Spare parts identification with chassis number

Digitisation is also being extended in the BPW Aftermarket Group. Garages can already use the upPlace web shop from the BPW Aftermarket Group to reliably identify the exact spare parts needed for individual trucks using the relevant chassis number. This search function enables garages to place orders in seconds for parts that they are certain are suitable for the vehicle. And with the QR code upLink, they don’t even need to enter the chassis number manually – they can simply scan the relevant QR code on the truck. This is based on an extensive database that matches up item numbers with the chassis number. There are plans to also optimise this principle for the trailer in future.

Mobile warehouse for garages

The BPW Aftermarket Group has developed the upBox (further information can be found in this article) to ensure that garages can access the right spare parts around the clock and to bridge the large distances between garages and spare parts dealers. The upBox is a mobile spare parts warehouse that can be used directly in commercial vehicle garages and by hauliers with their own workshop. It consists of a 40-foot walk-in shipping container fitted out with shelving, air conditioning, video surveillance and digital radio and security systems. A custom assortment of 1,300 to 2,000 spare parts is available around the clock. Each part has an RFID tag for automatic and contactless registration when a part is taken out of the warehouse. The system records all incoming and outgoing parts and updates the inventory data in real time. The billing, reordering and restocking processes are fully automatic. Stocks of spare parts are replenished the next day. This also means that stocktaking can be completed in a matter of seconds, at the click of a mouse. Ralf Maurer, Managing Director of BPW Aftermarket Group Deutschland, explains: ‘The upBox makes our customers’ day-to-day work much easier. We are sure that garages will be enthusiastic about this innovation.’