Reading time approx. 3 minutes

Text: Juliane Gringer

Photos: Alexander Volkmann/FUNKE Mediengruppe

Extreme conditions such as intense heat and rough terrain place great demands on transport vehicles, and especially on their running gear: with the help of BPW axles, low-loader manufacturer Faymonville designs robust, stable trailers that safely transport loads such as this 150 tonne tank over unpaved roads to their destination. This article is part of a series on exceptional transport operations on BPW axles over the past 125 years. Episode 4: Desert transports!

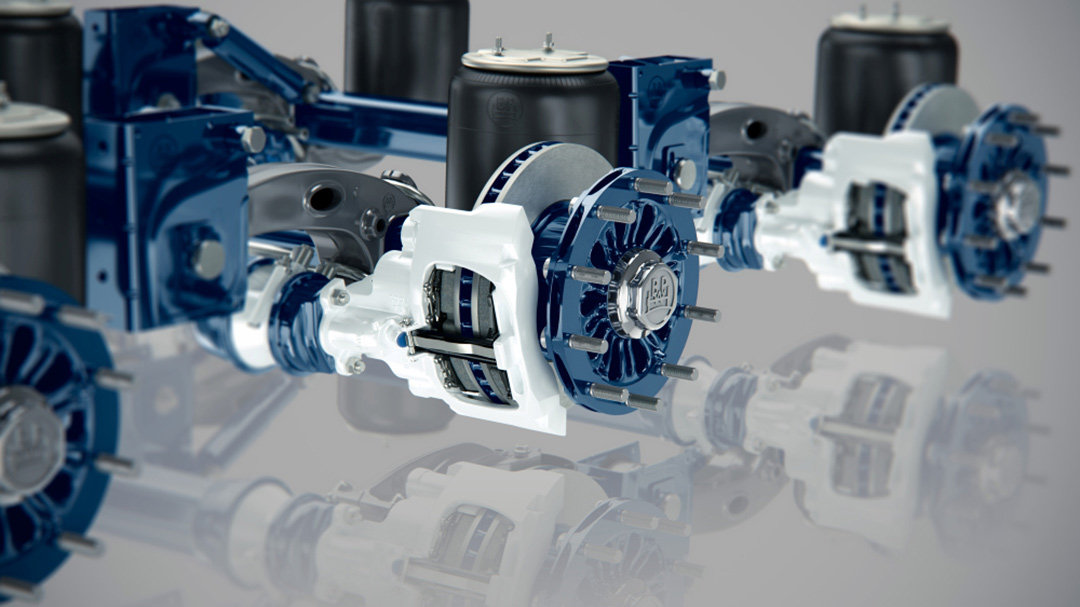

1,600 kilometres on mostly unpaved roads through Algeria, a journey over sand, gravel and washed-out tracks: the team was confronted with extreme conditions when transporting this 150-tonne tank. The transport company Groupe Chakour brought the 18.5-metre-long tank from the port of Arzew on the Mediterranean Sea to the south-east of the country. Here, the transport specialists relied on a vehicle combination comprising ten modular ModulMAX G-SL axle lines with BPW swing axles. These were built by Faymonville, one of the leading manufacturers of Low-loader trailers, to customer-specific requirements. Rainer Noe, Product Manager at Faymonville, explains: “For such projects, real off-road terrain has to be mastered much of the time: stony, dusty, sometimes precipitous paths. We know conditions like these from many operations, especially in Africa and Asia, but every time they present a new challenge.”

Withstanding heat and mechanical forces

Algeria lies in different climatic zones, but the climate there is predominantly dry and hot. Most of the south of the country is part of the Sahara desert, where the temperature quickly rises above 40, sometimes even 50 degrees Celsius and more in summer. And this is precisely the kind of thing for which the ModulMAX modular vehicle series from Faymonville is designed – for on-road and off-road use and climatic conditions ranging from blazing hot 50 degrees Celsius in the desert to icy cold minus 40 degrees in Siberia. “Anything above 40 degrees plus starts to make certain demands on the equipment,” Rainer Noe explains. “Above all, this affects the tyres: they have to be able to withstand the heat and the mechanical forces. Heavy transports are driven at rather low speeds of around 30 to 40 kilometres per hour. There, the load due to the weight is a much more important influencing factor.” According to Noe, the temperature extreme in the other direction – severe cold with sub-zero temperatures from around minus 30 degrees Celsius – is particularly challenging with respect to the equipment: “At very low temperatures, even metal can become brittle.”

»When we drive through dirt roads softened by rain, the whole axle can quickly be covered with mud. These are really extreme conditions. These really are extreme condition.«

Rainer Noe, Product Manager at Faymonville

High pressure on the ground

The boiler that the design from Faymonville moved through Algeria weighs 150 tonnes. This places a load of no less than 185 tonnes on the rear part of the vehicle. A correspondingly high pressure also acts on the ground. “It often happens that running gear sinks into the ground because the substrate is not capable of bearing such loads. Or if you drive over a drain cover, it breaks because it is not designed for such a load. It is also difficult to plan many things in advance: “For example, a stream can quickly burst its banks due to heavy rain and suddenly become an obstacle that we had not foreseen.

Stone chips, stirred-up sand and mud

At high speeds, the impact of stone chips is often high: “Drivers of passenger cars know this, too – when you drive along a gravel road, you get a lot of clattering in the wheel arch,” says Noe. But on trucks, a lot of technology is installed there.” Sand is also constantly churned up from below, impacting against the equipment. This means massive loads, which are especially hard on the Axles and wheels over time. “When our vehicles drive through mud, the whole axle can quickly be covered with it,” he continues. “These really are extreme conditions.”

Stability, robustness – and simple technology

The transport vehicles used must have the appropriate stability and robustness – and in the best sense, the simplest possible technology: “We don’t need a lot of sensors or electronic components in the chassis; it’s perfect if the axles are quite mechanically constructed. Simple, robust technology that can also withstand the ingress of dirt or water from the outside. Furthermore, reliable bearings are essential: “To compensate for unevenness in the ground, the axles must be very flexible – while the load remains consistently high. And the bearings in the axle are responsible for this.”

»The variety of axes we need is large. BPW can cover almost everything or has made modifications possible.«

Rainer Noe, Product Manager at Faymonville

Good exchange of ideas in the event of technical questions

A family-owned company with 800 employees, Faymonville builds Special vehicles for road transport. “We have by far the largest and most varied product range in this sector,” says Rainer Noe. Around 3,000 vehicles leave the factory halls each year. For some time now, the company has relied entirely on BPW when equipping new vehicles. “The variety of axles that we need is large. BPW can cover almost everything or has made modifications possible. We work closely together and we are now on first-name terms with the design team,” says Rainer Noe. “Whenever we have technical questions there is always a good exchange of ideas. In the same way, BPW also comes back to us to learn from our experiences.” And sometimes the customers want BPW too: “Groupe Chakour explicitly requested BPW axles for this transport through the Algerian desert.”

Whenever a new transport is planned, the Faymonville team analyses all of the framework conditions together with the customer, for example the axle load or the nature of the ground. “Ideally, the route to be covered has already been driven beforehand so that, for example, sections where the tipping limits are exceeded can be avoided and a vehicle with sufficient tractive power is selected – sometimes you need a second or third tractor unit to overcome gradients.” And naturally, sufficient braking power is just as crucial.

SpaceX will be brought to Cape Canaveral on BPW axles

Our customers always include outstanding names. One of the latest contracts for Faymonville: Elon Musk’s space company SpaceX has ordered a second combination to transport rockets. These are 60 metres long – the width of a football field. The vehicle, which is equipped with BPW axles, is to be transported from the West Coast across the USA to Cape Canaveral in Florida. “In particular, we must precisely prove the safety of the transport with our vehicles through concrete calculations in advance,” says Rainer Noe. “Every project has its own challenges, each of them is individual. That’s what makes our job so appealing and also so enjoyable.”

Faymonville

Faymonville has its roots in Rocherath in the German-speaking part of Belgium. Today, the company is part of the Faymonville Group, headquartered in Luxembourg, and is internationally established as a manufacturer of semi low-loaders, Low loader trailer, Modular vehicles and self-propelled vehicles for the special and heavy-haulage industry. With the MAX Trailer concept, there is also a modular construction system with which vehicles of the highest quality can be configured as required. In 2017, Faymonville acquired the Italian vehicle manufacturer Cometto, a specialist in heavy-duty modules, self-propelled modular vehicles and heavy-haulage transporters for industrial applications. This makes the company group a single-source provider in the heavy-haulage and special transport sector with transport solutions for payloads of between 15 and 25,000 tonnes.