Text: Kerstin Kloss, Juliane Gringer

Photos: Kerstin Kloss, BPW Otomotiv

The Turkish commercial vehicle industry is struggling with declining sales, but quality remains in demand, particularly in difficult economic times – more than 20,000 BPW axles and air suspension systems were assembled in BPW Otomotiv’s plant near Istanbul in 2018, and the company’s production output has tripled in the past five years.

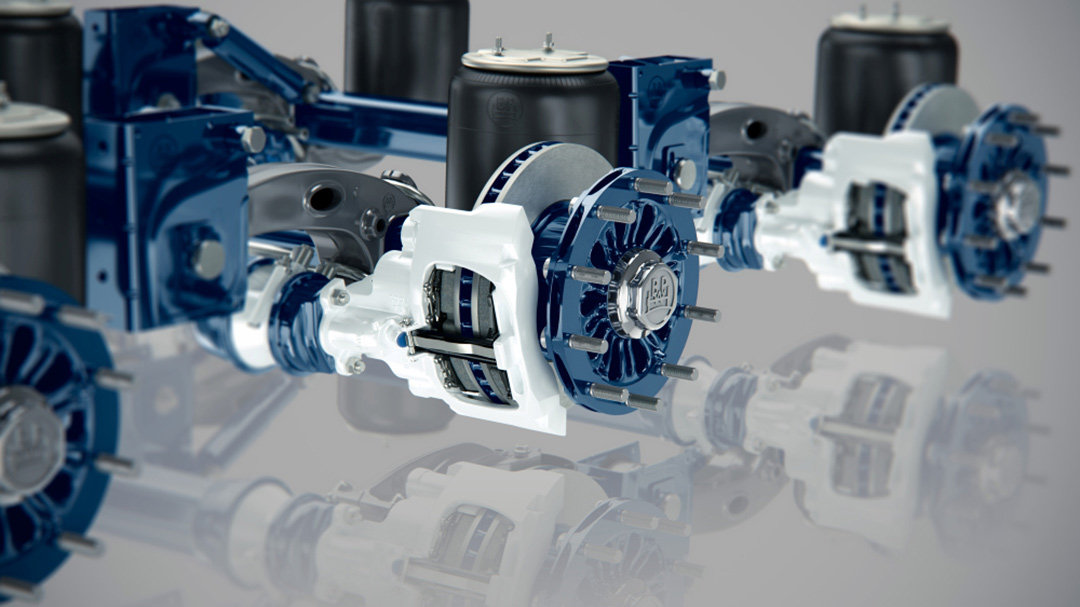

When you enter the building, you immediately notice how bright it is – the sun shines so intensely in Gebze on the Turkish Sea of Marmara that BPW Otomotiv’s 6,000-square-metre assembly and storage hall gets by without artificial light almost all day long. Even without lamps, employees can see every detail of the modular ECO Air running gear and AIRLIGHT II air suspension. And when it comes to their work, the details are of paramount importance – the standards by which BPW manufactures and markets its high-quality products are both high and the same worldwide.

BPW Bergische Achsen has been active in the Turkish market for over 30 years. It’s subsidiary BPW Otomotiv had long operated purely as a trading company, selling axles manufactured in Germany to vehicle manufacturers in Turkey. In 2005, the country adopted the EU directives applicable to trailers and thus also the corresponding EU standards, resulting in changes to the weight and dimensions of the country’s transport vehicles. This led to many old, overloaded vehicles being replaced by modern trailers, and the demand for BPW running gear increased rapidly. In the meantime, one out of every two commercial vehicles in Turkey is equipped with BPW running gear: ‘Our market share today is over 60 per cent,’ reports Hüseyin Akbaş, managing director of BPW Otomotiv.

Axle assembly in the near vicinity

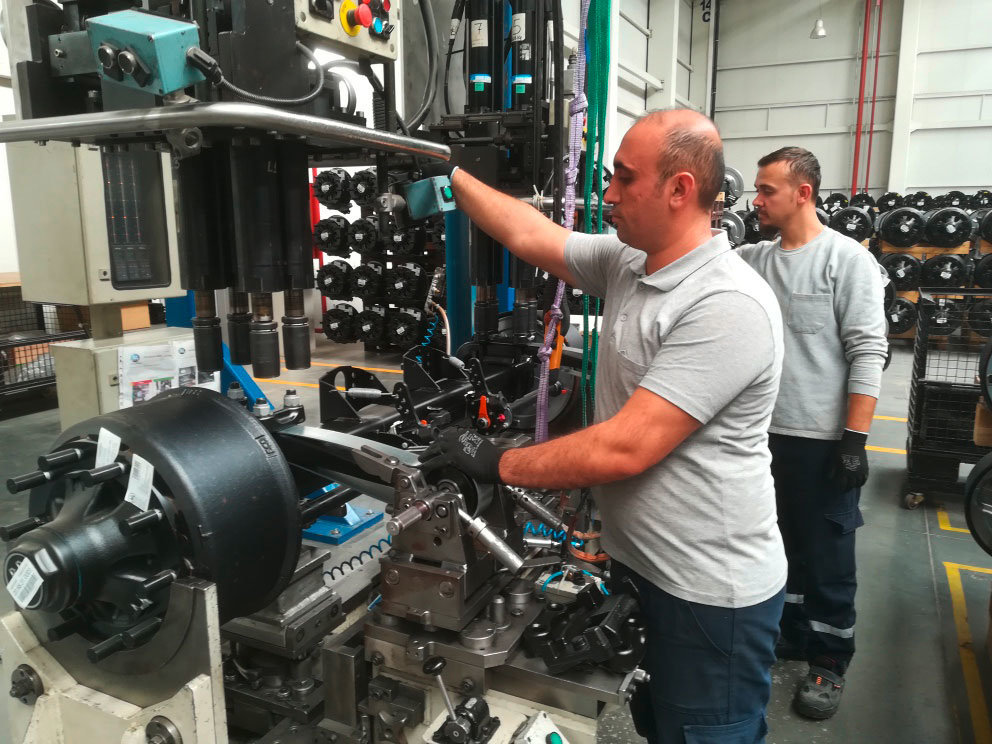

Plant Manager Gülsüm Çıǧın explains the process: ‘When a customer orders an AIRLIGHT II running gear from us, for example, we first assemble the wheel hubs. As the main component, the tapered roller bearing is then installed, which reduces frictional resistance and thus ensures that the wheel always runs smoothly.’ The parts for this are sourced from the headquarters in Wiehl or from external suppliers. Despite their lightweight construction, trailer axles and their components are still heavyweights – to lift fully assembled components from the pallet onto the assembly line, the employees use a special lifting device. Up to 120 wheel hubs are assembled per day. Like his colleagues, 28-year-old Tolga Kizilkus works on all the assembly lines in rotation. This makes axle production more flexible and the job more interesting. All employees undergo on-the-job training and receive written instructions: ‘After just one month, I was able to do everything on my own,’ he reports.

Focus on employees

Nearly 50 employees work at BPW Otomotiv. In order to remain attractive as an employer, the company pays close attention to the needs of its employees. Every Friday, a shuttle bus takes them to a nearby mosque; and flexible working hours make the long break needed for this possible. Twice a day, all of the employees get together to drink tea – an important ritual for sharing ideas. In Turkey, it is also common for employers to organise transportation to the workplace, which is why BPW Otomotiv has its employees picked up at various gathering points. The employer also provides meals free of charge.

Interaction with colleagues in Germany

The plant manager walks over to the axle assembly. Here, an axle beam is fused with a wheel hub connection and a disc brake calliper to form one axle. Then an employee pushes the assembled components further to the air suspension assembly. In contrast to the German BPW headquarters, production in Gebze still relies heavily on conveying processes with manual trollies: ‘For the volume we produce here, this is more efficient than with autonomously moving transport racks, ’ explains Çıǧın.

She now stands at the end of the assembly line. As soon as there are three axles on the pallet, a forklift truck takes them to the shipping area next door. All of the production data is saved digitally in special software. ‘This ERP system allows us to trace back how all of the parts were assembled,’ explains Çıǧın. She speaks with colleagues from the Wiehl plant almost every day: ‘This interaction is extremely important to us. Our co-workers there can connect to our system online at any time so that we can discuss questions quickly and directly. This is extremely helpful.’