Reading time approx. 4 minutes

Text: Juliane Gringer

Photos: Holger Jacoby, B & M Logistics-Service

To ensure that sensitive goods such as medication or fresh foodstuffs stay cool during transport, you need the best technology and the highest degree of reliability throughout the supply chain. That’s why the Hesse-based haulier B & M Logistics-Service and the sushi producer Natsu Foods from Neuss rely on telematics solutions from idem telematics.

»The solutions from idem telematics extremely reliable.«

Sushi is not a fresh product – it’s an ultra-fresh product. There are just a few hours separating the moment when the rice dishes roll off the conveyor belt at Natsu Foods in Neuss and the arrival of the delivery driver in one of around 2,500 supermarkets across Germany that are supplied by the company. New products are generally delivered to the chilled counters three times a week. The trays of maki, nigiri and other sushi treats then wait to be picked up by hungry shoppers – and they need to be able to rely on the freshness of the products.

Lars Gormanns manages the Natsu Foods fleet.

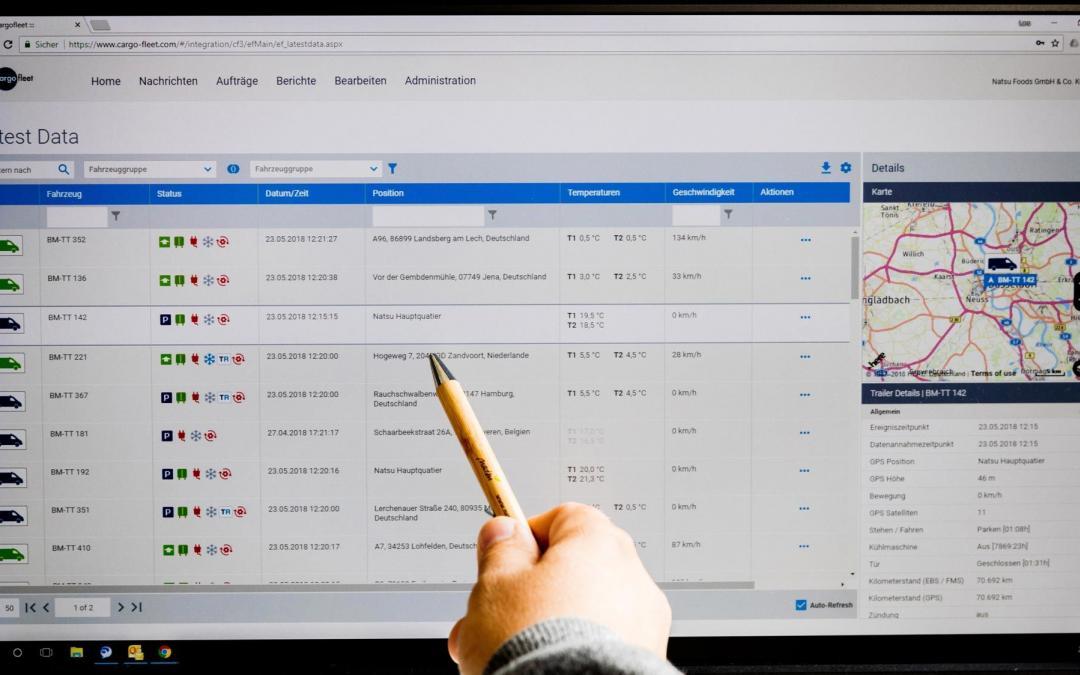

That’s why the company has been using TControl COOL T 110 from idem telematics for around three years. The telematics unit has been installed in 85 goods vehicles that are used by Natsu Foods over the last mile of the deliveries. The company uses an experienced service provider for the transportation into urban centres and the vehicles then carry out the next distribution phase in the target area. ‘Retailers and consumers have the right to the best quality and reliable supervision for the entire supply chain,’ says fleet manager Lars Gormanns. ‘Telematics can ensure that this is the case. The solutions from idem telematics are extremely reliable. The customer service is also flawless.’ Natsu Foods uses Cargofleet, and Gormanns appreciates the portal’s clear structure and ease of use. On the computer monitor on his desk, he can see which vehicles are currently on the road, whether they are moving or stationary, and – most importantly – whether the specified temperature is being maintained.

The drivers deliver the sushi quickly and directly to the supermarkets.

Natsu Foods was set up in 2004 by two brothers who had the vision of getting sushi into supermarkets. They now produce around 5,000 tonnes of sushi each year in Neuss and another 2,600 tonnes at their second site in Leipzig. The founders place great emphasis on sustainability and quality, using the best ingredients and transport making efficient use of resources. The maximum speed for the fleet has been limited to 140 kilometres per hour, which has reduced diesel consumption by 15 per cent. The drivers also receive regular training. Gormanns is watching the market for vehicles with alternative drives: ‘There isn’t a practical solution yet for the goods vehicles that we use. As soon as one exists, we will switch.’

»The products have more functions than those from other providers.«

Medications also place particularly high demands on transport – all the more so when it involves large distances. The haulier B & M Logistics-Service specialises in temperature-controlled transport of pharmaceuticals and blood supplies in the Middle East and central Asia. It delivers pharmaceuticals from European manufacturers to hospitals, pharmacies and health authorities in Bulgaria, Georgia, Armenia, Azerbaijan, Turkmenistan, Turkey, Iraq and Iran. The longest distance that B & M Logistics-Service covers is the route to Afghanistan: the vehicles are on the road for around two weeks, covering 7,500 kilometres.

But regardless of how far the vehicles travel, the sensitive load must be monitored at all times without interruption. The company caters for all temperatures from –25 to +25 degrees Celsius. ‘The temperatures have to be kept reliably constant and the doors must be securely locked,’ explains managing director Nurettin Büyükkoc. B & M Logistics-Service ensures that this is the case by using a telematics system from idem telematics. This has been installed in the company’s fleet since 2016 and enables comprehensive monitoring during transport. ‘We were particularly impressed that the solutions from idem are compatible with most of the systems used by our customers and have more functions than the products from other providers.’ This also includes documentation of the loading times and the tyre pressure. Deviations in the temperatures are reported with an alarm – as is unauthorised access to the trailer doors. Geofencing can also be used to define an area digitally. If the vehicle then leaves the area, the system triggers an alarm in this scenario too.

The B & M Logistics-Service vehicles often cover very long distances.

B & M Logistics-Service is planning to open its own warehouse in Germany in the near future with an associated fleet so that it can process greater volumes and build even stronger ties with its clients. ‘We are also currently undertaking in-depth work on data sharing,’ explains Büyükkoc. ‘We see a great deal of potential in this area.’