Text: Oliver Schönfeld

Photos: BPW

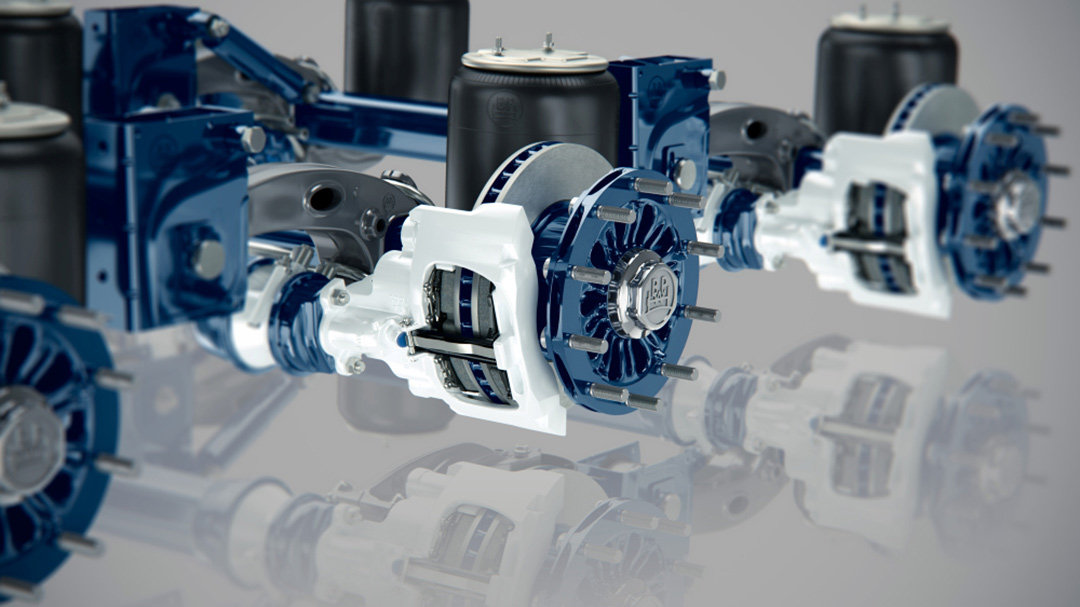

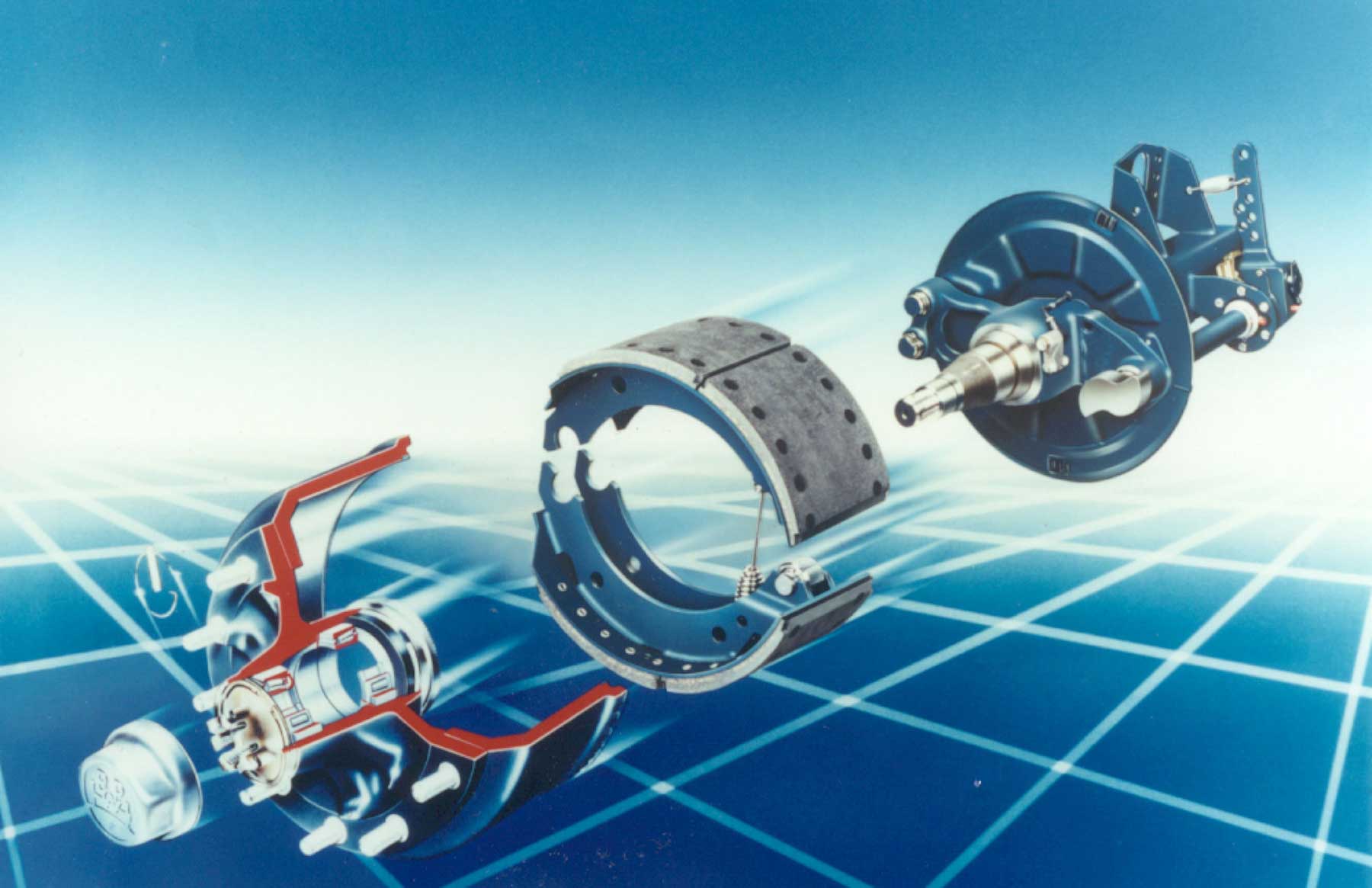

Innovations turn into sustainable success stories when they offer users real added value. The ECO principle from BPW Bergische Achsen is a good example of this: it offers especially time-saving and hence cost-saving assembly and disassembly of the axle hub, including the rim and tyre.

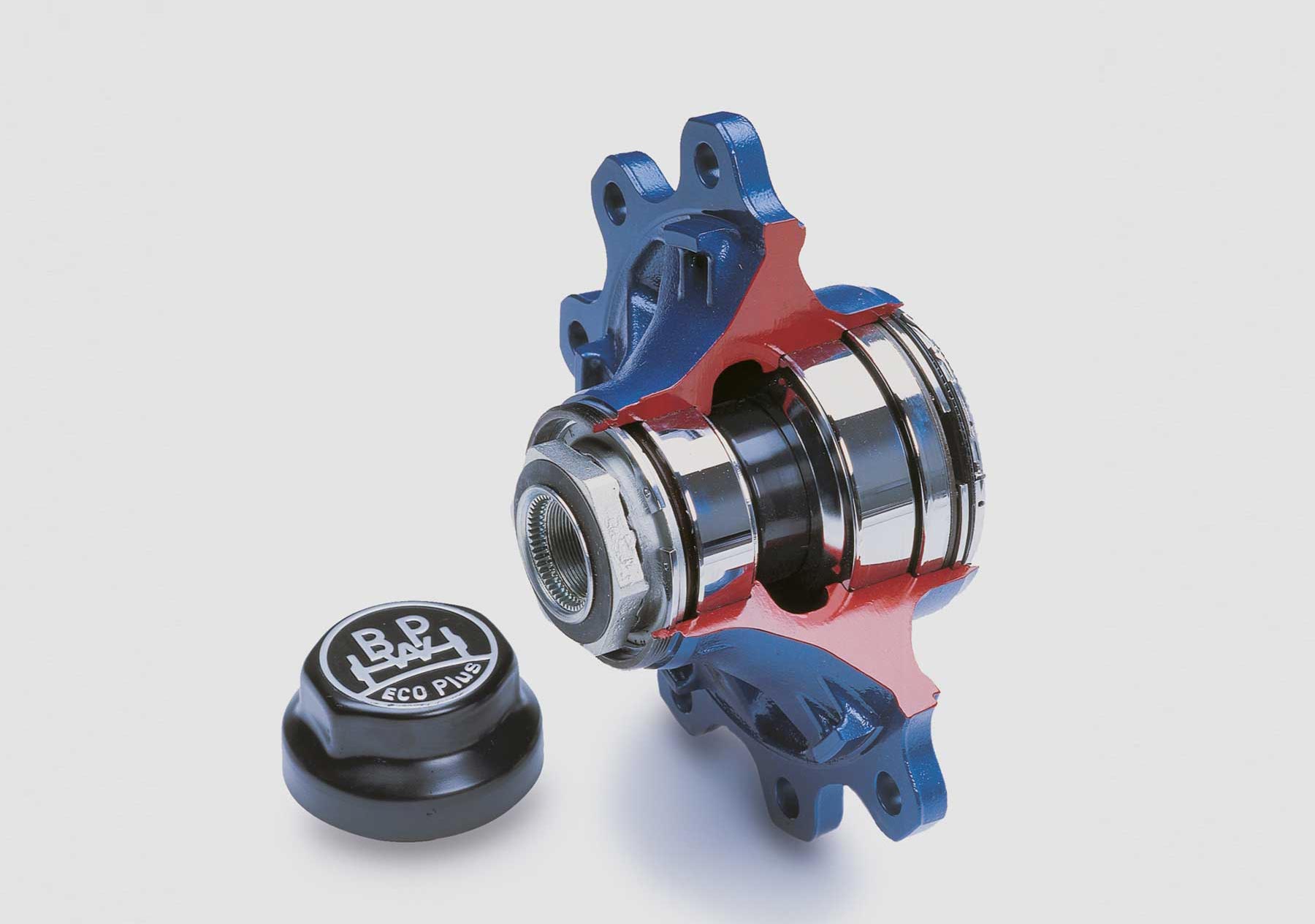

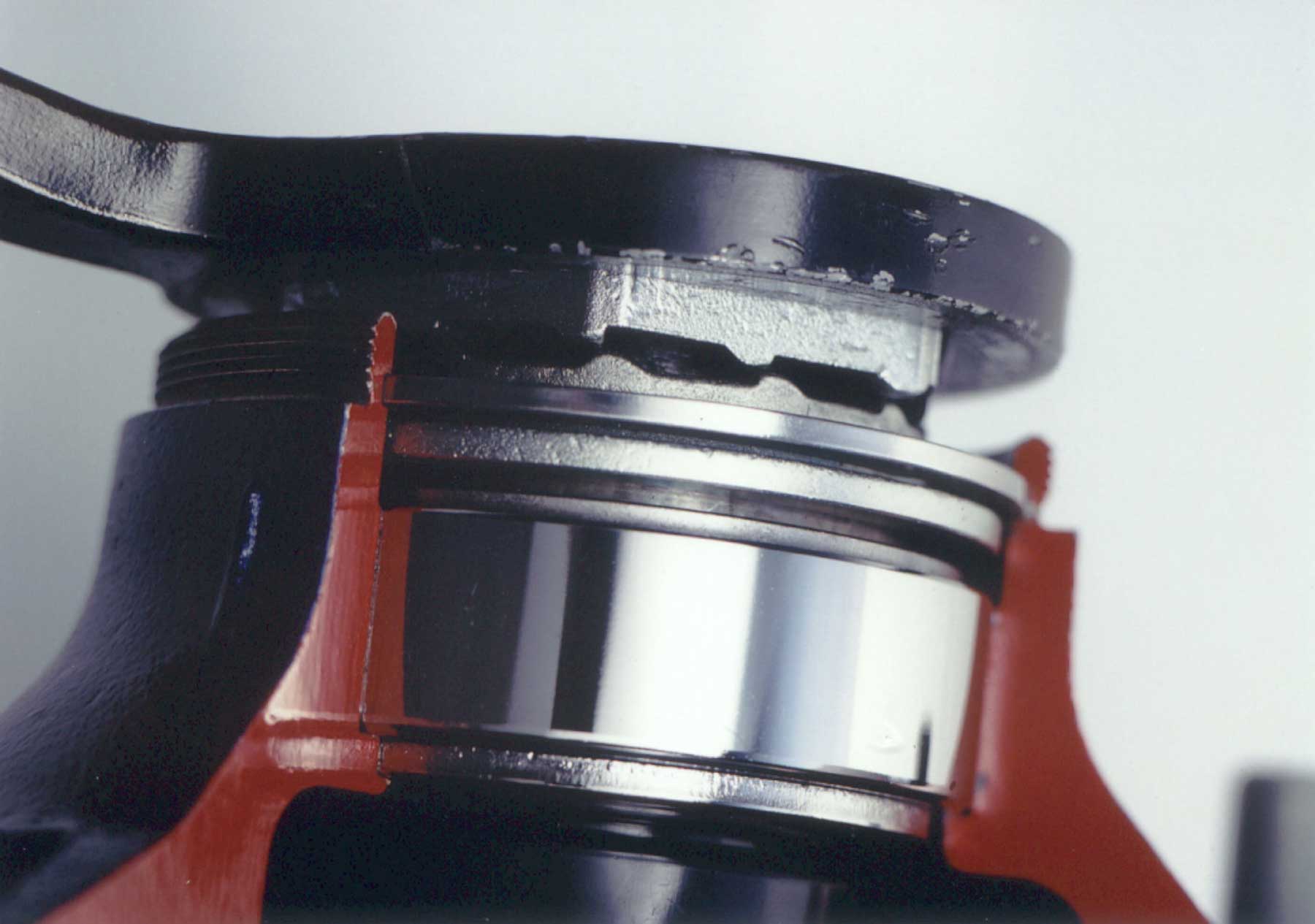

During Formula 1 pit stops, tyres are changed, fuel tanks are filled, damage is repaired and parts are replaced at record speed. Really good teams complete the most important steps of this procedure in as little as two seconds! The BPW development engineers were inspired by this fascinating process when they were faced with the following question: how can the replacement of brake wear parts on the trailer be made easier, safer and especially faster? At the end of the 1980s, their idea matured into a production-ready solution. Just like in motorsport, the BPW ECO hub only requires the loosening of a central axle nut connected by snap rings. Then the wheel can be directly removed on both drum and disc braked trailers without separating the two rows of bearings. This removes the need for re-greasing, as the wheel bearings remain in the wheel hub where they are well protected from the ingress of dirt during the assembly process.

Reduce downtimes

“When the axle nut is unscrewed, the sophisticated design means that the hub is detached from the steering knuckle,” explains Michael Schwarz, Head of the Patent and Trade Mark Rights Department at BPW. “The axle nut itself becomes a tool and thus renders the otherwise necessary pullers for dismantling the drum-hub unit superfluous.” The solution, which was patented at the time, thus saves several work steps in one go.

The resultant time saving when changing brake wear parts or bearings is up to three hours for a three-axle semi-trailer compared to conventional solutions offered by the competition – a sustainable benefit for both the workshop and for the transport company. “Naturally, this advantage applies to regular maintenance as well as to unplanned repairs on the road. After all, who carries the special tool for pulling off the hub with them all the time?” says Schwarz.

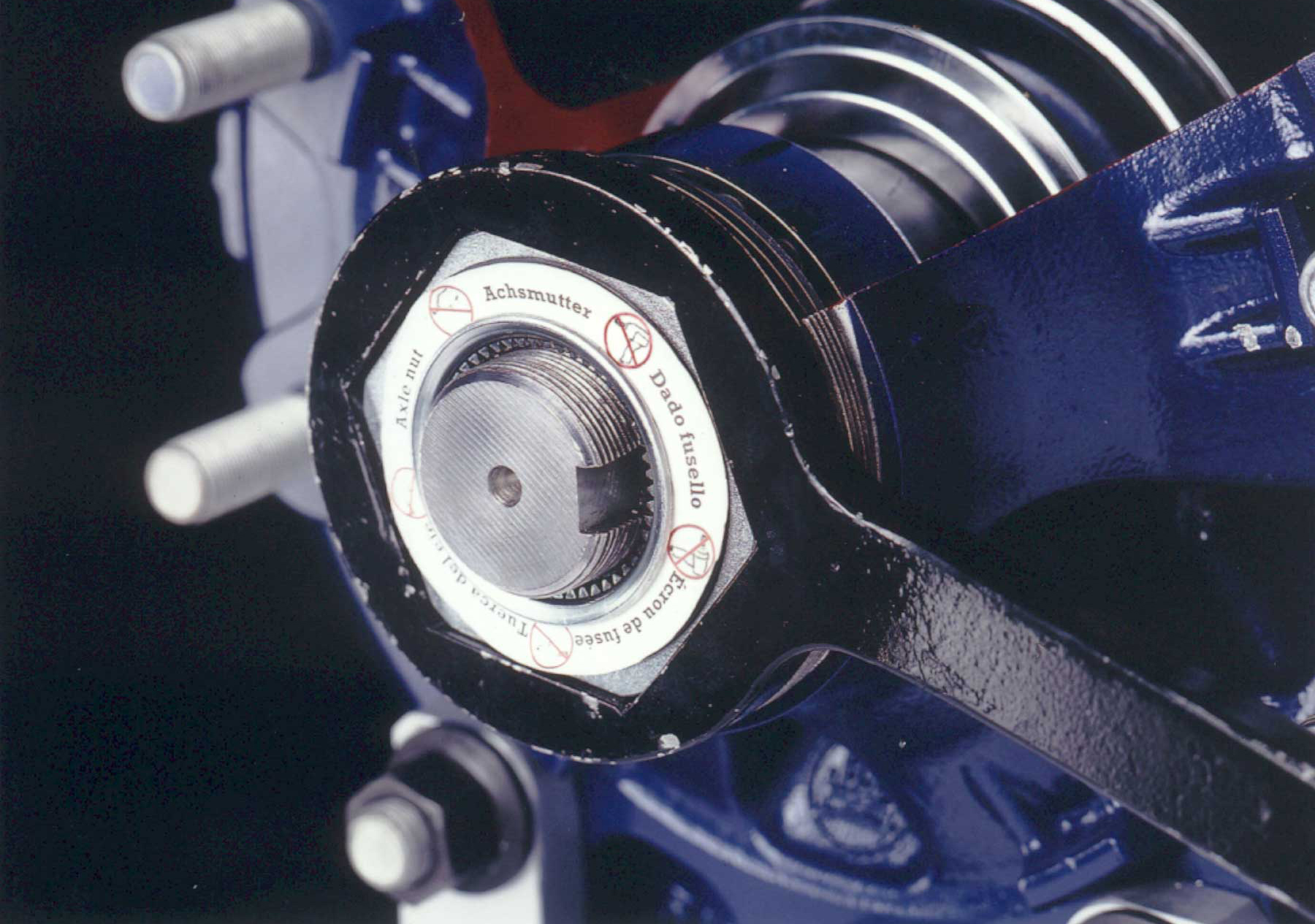

The ECO hub was granted a European patent in 1993. It set new standards in ease of maintenance, the principle has proven itself on many thousands of trailers and is now established as the market standard. But the BPW team did not want to rest on its laurels, instead it continually creates additional advantages for more economical vehicle operation through further developments. So the ECO hub was not the end of the story: just a few years later, the torque-limited axle nut was patented as a central component of the ECO principle.

Axle nut with torque limit

»Overall, the ECO principle is a recipe for success that is used in thousands of cases today and is appreciated by haulage companies and workshops alike.«

Head of the Patent and Trade Mark Rights Department at BPW