Text: Oliver Schönfeld

Photos: BPW

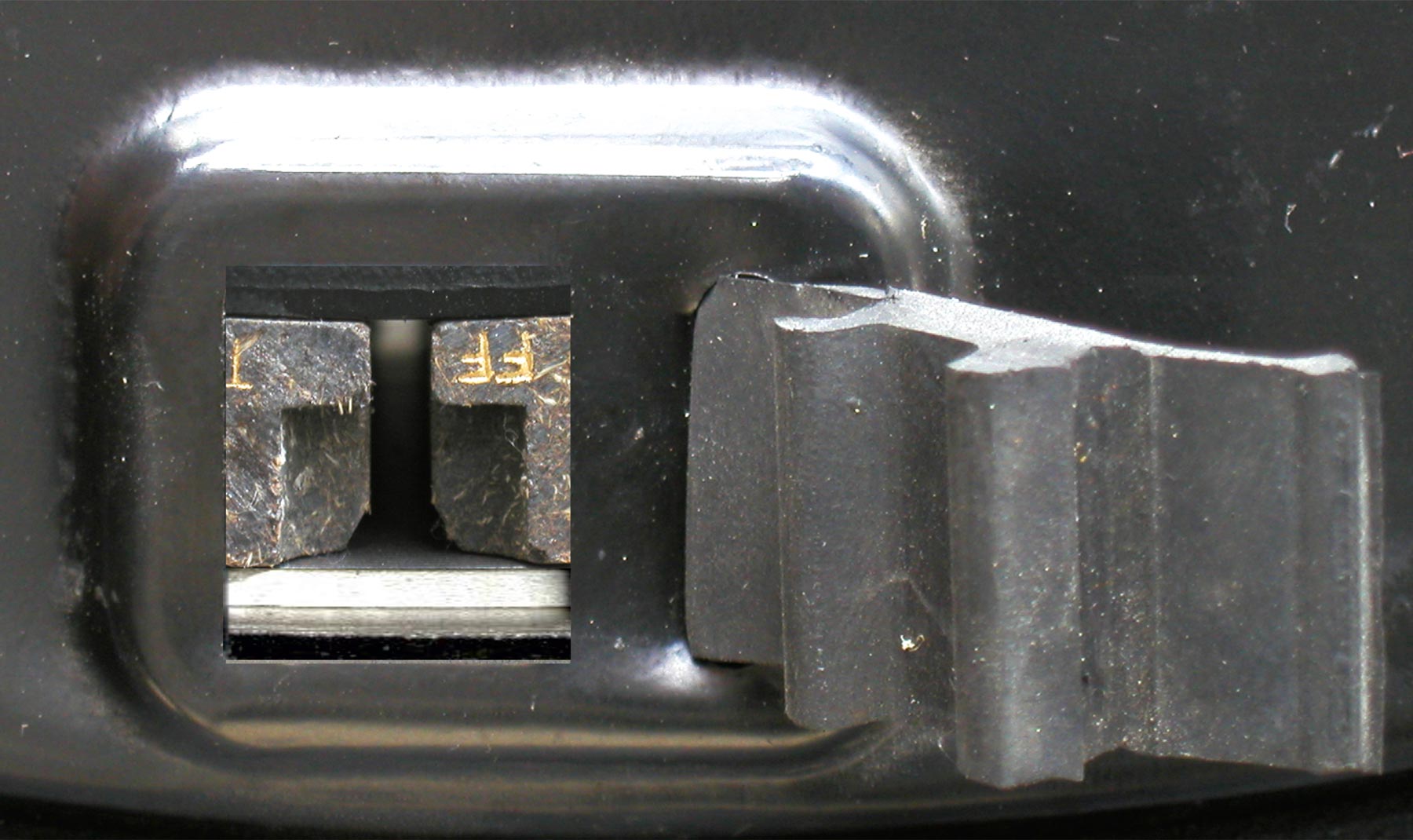

Brakes are vehicle components that are relevant to safety. Brake drums and brake pads must also be checked regularly on trailers. A development for which BPW applied for a patent back in 1992 provides greater clarity in terms of wear – in the truest sense of the word.

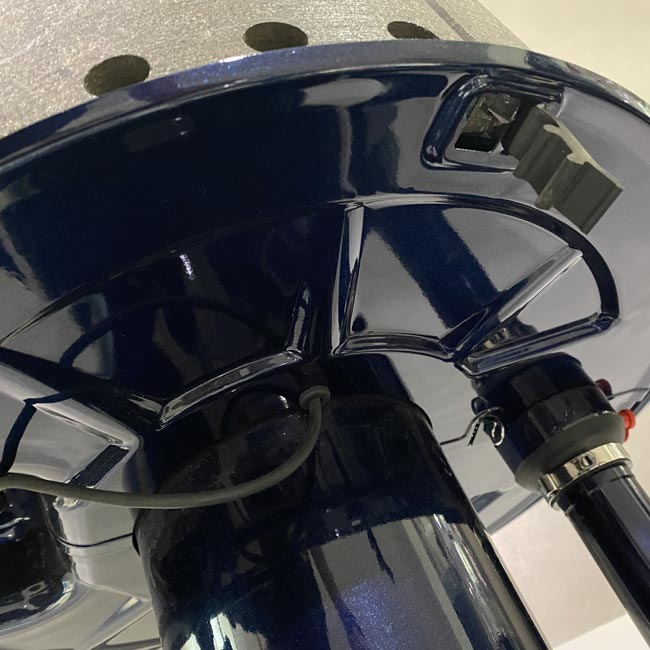

Wear check via inspection window

Express brake service

But BPW’s innovation has not only made it much easier to check the trailer for brake wear. The replacement of wear parts saves just as much time and is just as uncomplicated: together with the torque-limited axle nut, BPW’s ECO Technology provides servicing that is almost as fast as in Formula 1. This is possible as the friction linings cannot work their way into the brake drum due to the fold that is present around the circumference of the brake drum, which means that no edge is formed that makes it difficult to remove the brake drum. . The patent specification from back in 1992 states: “The invention thus kills three birds with one stone by allowing better control of brake lining wear and brake drum wear and at the same time eliminates the need to rework the brake drum during brake lining replacement.”

High levels of reliability for decades

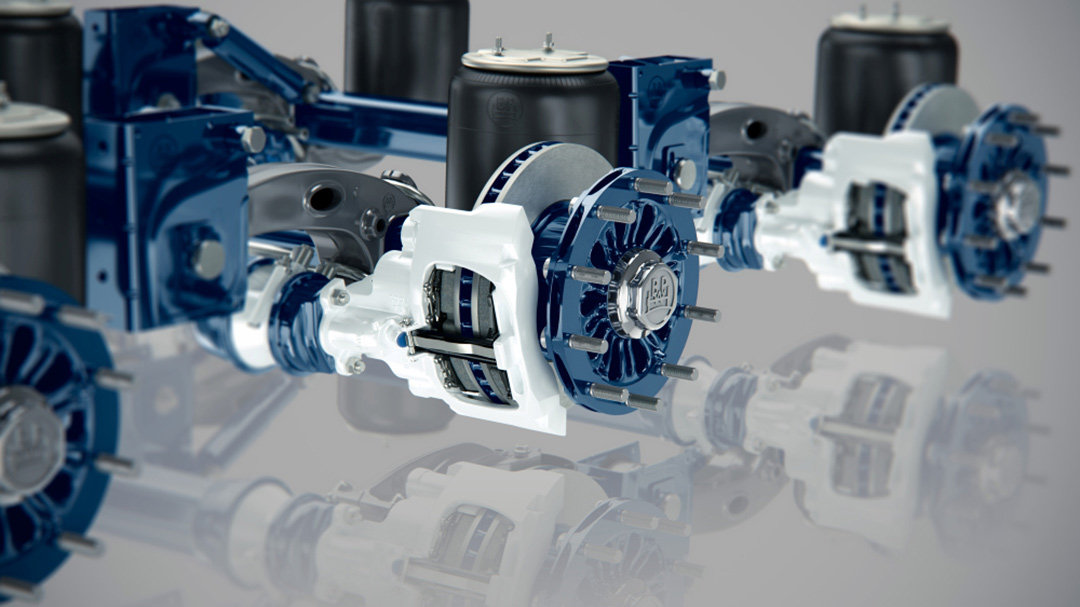

With more than eleven million units sold, BPW’s Drum brake ECO Drum has proven its reliability for towed vehicles over many years. Optimised friction pairing with the brake drum guarantees minimum wear and high performance. And the wear indicator allows a visual check in seconds – because safety comes first!