Reading time: approx. 8 minutes

Text: Juliane Gringer

Photos: adobestock-ra2-studio, Paul Kranzler, BPW

Martina Mara is Professor of Robot Psychology at the Linz Institute of Technology (LIT) of the Johannes Kepler University Linz. She is carrying out research on how robots and humans can work well together, and what is key to ensuring we do not fear machines. How can driverless vehicles gain our trust, for example?

Martina Mara: At my institute, we don’t have any humanoid robots sitting on a therapy sofa, quite the contrary: as robot psychologists, we are concerned with the well-being of people when dealing with machines. Psychology often deals with people’s experiences and perceptions, i.e. how – as humans – we experience our environment, how we react to it and how our perceptions influence our behaviour. In robot psychology, we deal with the issue of how humans perceive different types of robots, how we behave towards them and how they should behave towards us. We are researching how artificial intelligence can be designed to offer pleasant interaction for different target groups, and how not to feel dominated or frightened by intelligent technology, for example.

»Human beings and their complex nature should not be replaced, but rather be supported by machines’ strengths.«

Martina Mara, Professor of Robot Psychology at the Linz Institute of Technology (LIT) of the Johannes Kepler University Linz

Preserving human autonomy, a subjective feeling of security and trusting the robot as a teammate. When working with a robot, I must be able to assess what it will do next. I must be able to read where it is moving to, where it stops, whether it has seen me and will brake for me. The robot must also be able to analyse: what are the humans doing? Sophisticated sensor systems and machine learning systems are used for this purpose.

As part of our ‘CoBot Studio’ research project, we are currently building extended reality environments where we are merging virtual reality with robots and physical objects to simulate future working environments in which humans work very closely with robots. There, we are testing how a robot should communicate with different people in certain situations and what signals it has to send, and when, in order to be as readable and predictable as possible. In these simulation environments, we are also investigating the relationship between the robot’s clarity and the actual influence on a human’s subjective feeling of safety and well-being. And, of course, we’re looking at collaborative success: do I really work more efficiently with a robot if I truly understand what it can do?

I think that in many cases portrayed in the media, it is not so easy for us humans to become completely replaceable. We should not underestimate our cognitive, motor and social skills. One such example is our highly developed human dexterity: since we learn this early on in childhood, we automatically know how firmly we can grip certain materials, what finger pressure is required to hold a drinking glass or a cup made of plastic or styrofoam. In contrast, robots have to be taught all this very laboriously. In order to counteract fears of these new technologies and to develop positive images of the future, it’s crucial that we show how humans and machines can complement each other.

Human beings and their complex nature should not be replaced, but rather be supported by machines’ strengths. We don’t often see such synergetic images of humans and machines. The media usually conveys an impression of almost magically powerful, sometimes even very human-like machines, and these messages give the very distinct feeling that they can and should replace us. But a doctor, for example, certainly cannot be completely replaced by an AI algorithm – this is utterly absurd for a variety of reasons. But we are still afraid of this happening. We should therefore instead show what is realistic: that doctors could use an algorithm – an AI system – to support their decision-making. Combined with human experience and communication skills, this would lead to good results.

Training centre for robotics

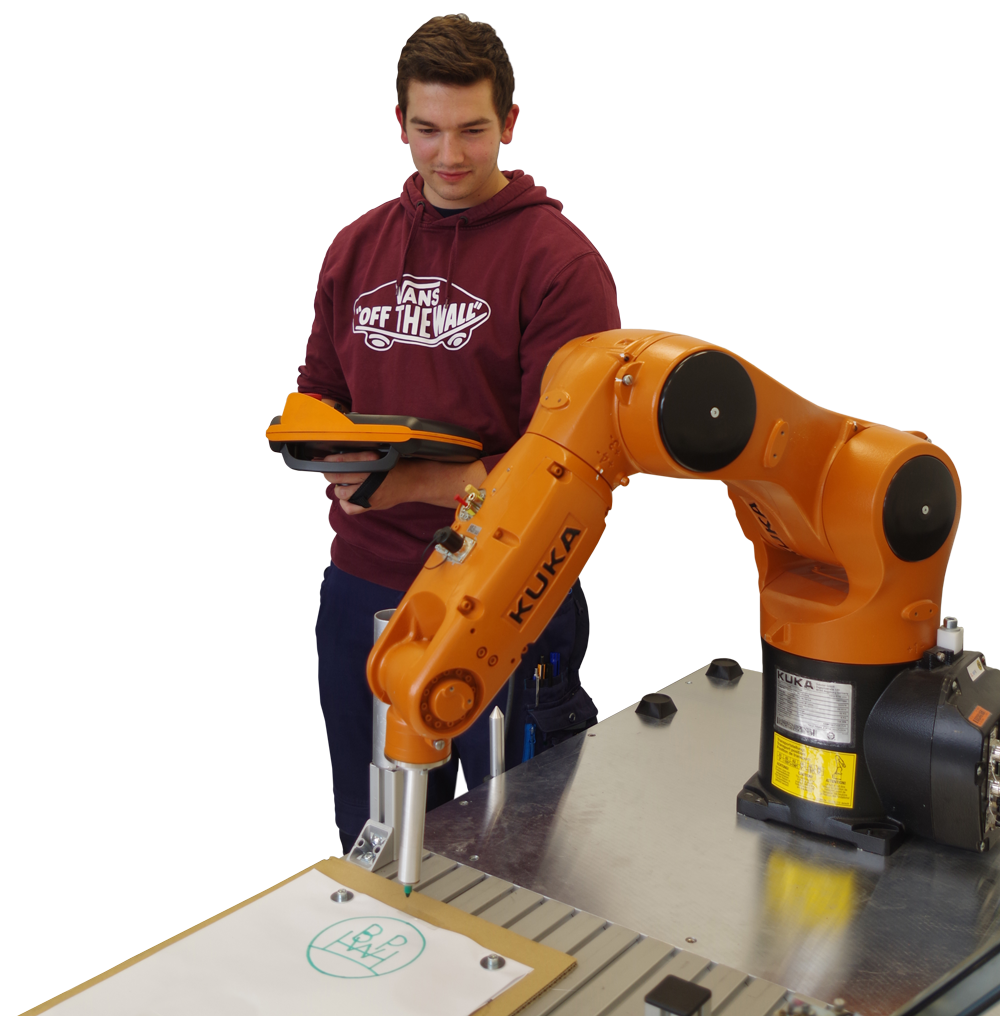

How can we work safely with robots? This is what BPW Bergische Achsen trainees learn at the ‘Robotics Start-Up Days’: with their own robotics training centre, trainees, employees and students can all learn how to operate, maintain and program state-of-the-art robots under production-related conditions. Two Kuka six-axis robots have been specially installed in the training centre. These courses last ten days; the first two took place in spring 2019 for trainees in the field of electronics and mechatronics. Future industrial mechanics will also participate in 2020.

‘Working with robots creates more tasks at a higher level, and these tasks are more complex,’ explains Felix Rudat, electronics and mechatronics trainer at BPW. ‘That’s why we believe that this should be dealt with early on in the training. With our training courses, we particularly wanted to overcome inhibitions, show how to handle such a device and how to operate it manually, too.’ BPW is using more and more robotic systems in the mechanical production and machining of components, for welding, handling pallets and workpieces, and finishing machined parts, for example. ‘In doing so, the robot often not only solves one task, but, as it is usually a multi-gripper, can solve several complex tasks. For example, they no longer pick up just one part, such as a brake caliper, but several parts and distribute them,’ says Rudat.

Niklas Thomas, who is being trained as a mechatronics engineer at BPW, took part in the Robotics Start-Up Days. His conclusion is positive: ‘I particularly liked the fact that we stood directly next to the robot during the training and tried out a lot ourselves. This enabled me to gain a good awareness of the machine. You have to just feel the rotational axes of a robot to understand them.’ Another important learning objective of the workshop was to raise awareness of health and safety issues related to working with robots: ‘We worked together to determine what dangers can emanate from such a system and wrote an instruction manual explaining what needs to be considered when working with and alongside robots,’ says Thomas. This includes backing up data and having a sense of where your own limits are in dealing with the devices – and when to seek assistance.