Reading time: approx. 3 minutes

Text: Juliane Gringer

Photos: Paul Nutzfahrzeuge

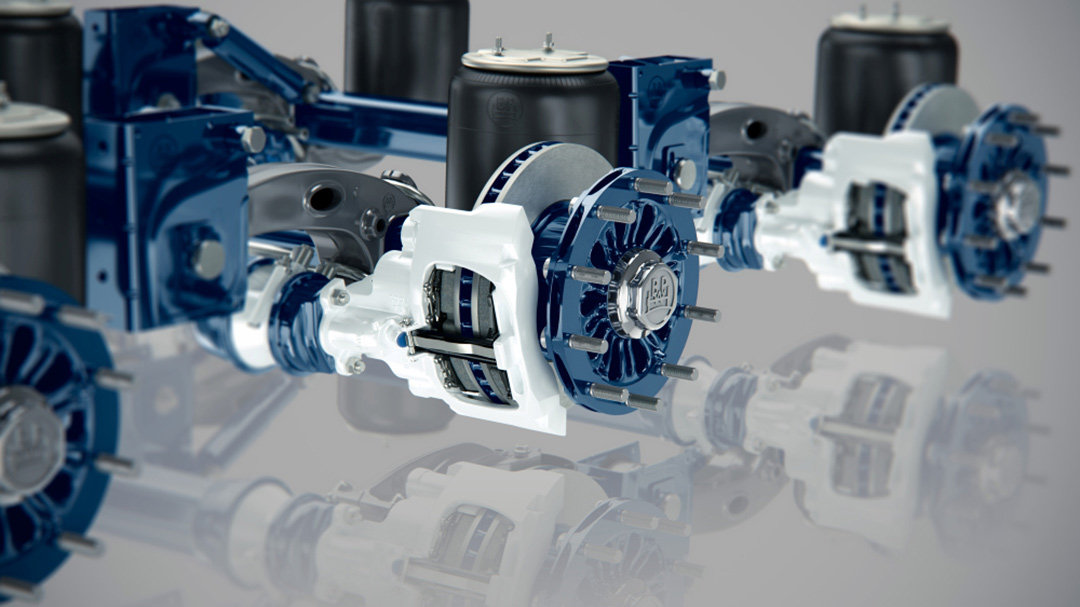

eTransport – the e-drive system from BPW – proved its strength in a special test: Paul Nutzfahrzeuge drove a converted Mercedes-Benz Vario with almost two tonnes of beer emission-free to the Großer Arber in the Bavarian Forest.

Can an electrically driven 7.5-tonne truck take a large load of beer to an altitude of 1,455 metres? Yes, it can! Paul Nutzfahrzeuge from Passau ventured this unusual transport: over some 20 kilometres of gravel roads, a special truck converted with the electrically driven axle eTransport from BPW Bergische Achsen was used to transport the beer. The vehicle mastered the route with flying colours despite a 24 per cent incline in some places – and delivered almost two tonnes of beer from the 1st Zwiesel Steam Beer Brewery to an inn with zero emissions. “We had confidence in the technology – but the fact that everything went so smoothly impressed me very much, to be honest,” reports Bernhard Wasner, Managing Director of Josef Paul GmbH & Co KG. “The E-axle is a real powerhouse. And our little project proves once again that new technology can also prove its worth under special challenges in practical use.”

Climate neutral beer transport

»We trusted the technology – but the fact that everything went so smoothly impressed me very much.«

Bernhard Wasner, Managing Director of Josef Paul GmbH & Co. KG

No loss of grip even on steep, stony paths

Only 30 per cent battery charge consumed

Implementation in practice planned

Wasner draws an all-round positive conclusion. “I have to say: it is a great achievement of the BPW axle that you can dose the power so well in such a transport and that there are no disadvantages whatsoever. The product has not been designed for this type of application –but the fact that it masters them anyway is great! I was really fascinated by the fact that the electric axle eTransport can also master such extreme challenges.” He sees this as proof of the strong future viability of the technology. And for the fact that things are worth trying out: “That was a cool move! It also reminded me that you have to get out now and then and try unusual things.” For the Arberschutzhaus and the three other excursion venues in the Bavarian Forest, the successful test means that they may soon be able to supply emission-free goods: “We are in discussions and are trying to make this possible with the help of subsidies.” Wasner hopes that every “Cheers!” on the mountain might then be climate neutral as early as next year.