Text: Manfred Schulze

Photos: Thomas Meinicke Photography, KIROW ARDELT GmbH

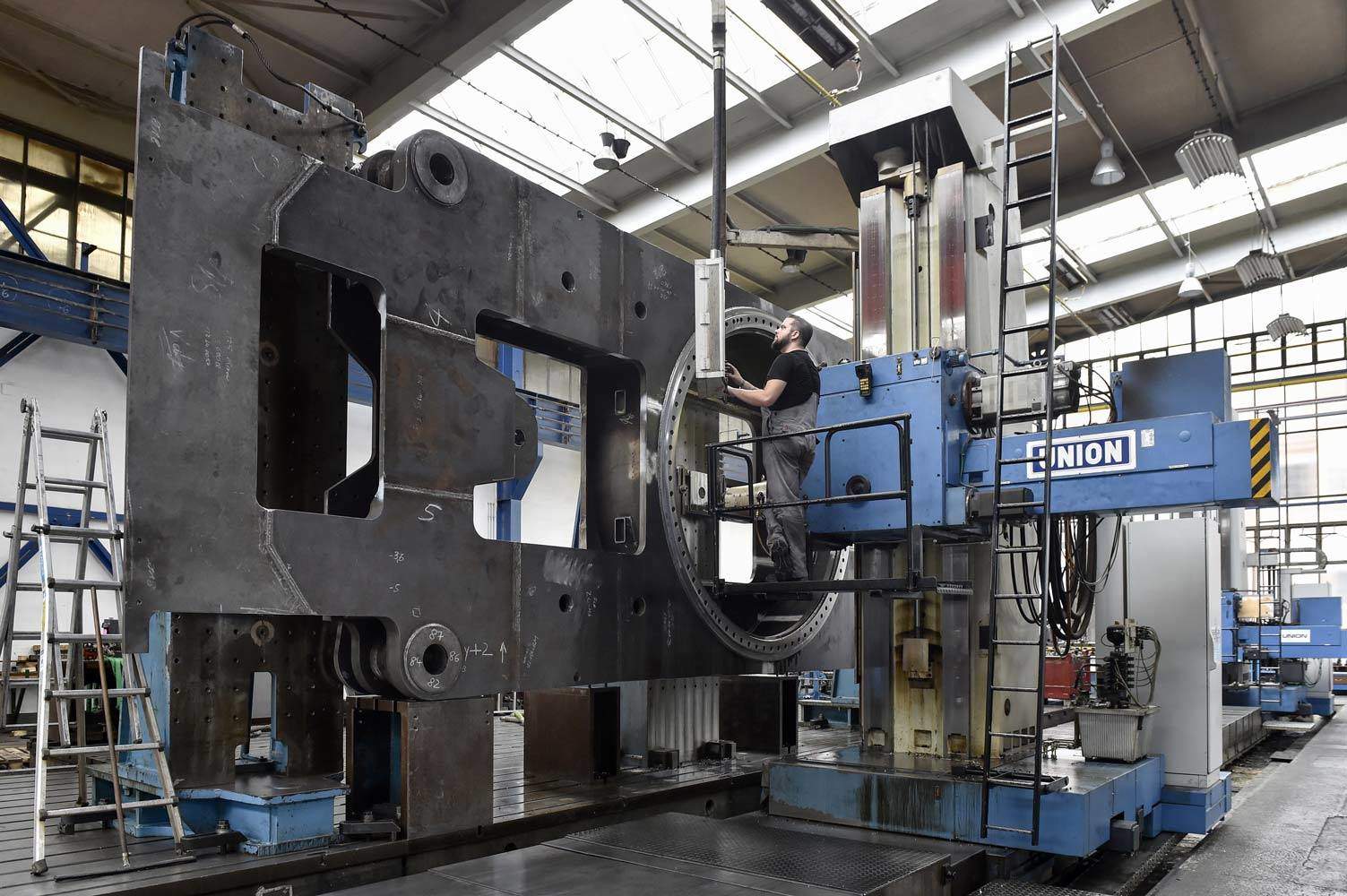

Millions of tonnes of goods are moved each day. Innovative transport systems are vital for this. The mechanical engineering firm Kirow Ardelt from Leipzig is known around the world for building railway cranes and heavy-duty transporters.

A location with tradition

On the nearby testing floor, a brand-new railway crane can be seen in full action – these giants of the tracks helped Kirow to gain great prominence back in the GDR era. ‘They are in use around the globe – not just in Germany, Russia and China, but also in Indonesia and Brazil, for example,’ says Erdmann.

The ‘Multi Mover’ success story

One of the most powerful transport systems was produced in summer 2018 for the shipbuilding company MV Werften in Stralsund: the new ‘Multi Mover’ can transport up to 380 tonnes across the shipyard. It carries loads such as complete sections of the ship’s shell and moves them into place for the final assembly of the hull at a speed of up to six kilometres an hour. The shipyard has been using ‘Multi Movers’ from Kirow for several years and has now added a fourth vehicle to its fleet.

The ‘Multi Mover’ is six metres wide and almost 18 metres in length, including the compact driver’s cab installed below the platform. In addition to the three hydraulically driven axles, the vehicle also has three running axles and six braking axles, which can all be steered individually. ‘To implement such a demanding project, we need reliable partners with a great deal of experience,’ explains Erdmann. ‘BPW has the expertise and the ideal products.’

»TO IMPLEMENT SUCH A DEMANDING PROJECT, WE NEED RELIABLE PARTNERS WITH A GREAT DEAL OF EXPERIENCE.«

Gunther Erdmann, project engineer at Kirow Ardelt

Spectacular and ordinary at the same time

The moment when the finished vehicle is started for the first time at the commissioning point is very special: ‘it is always a fascinating experience for me when such a huge vehicle is finally finished,’ says Erdmann. ‘After all, we have been working on this project for months, we’ve seen it grow piece by piece and encountered many new challenges.’ For Kirow, the orders are always spectacular and ordinary at the same time. ‘Meeting the individual needs of our customers is the biggest challenge for us – and is also the best thing about our job.’

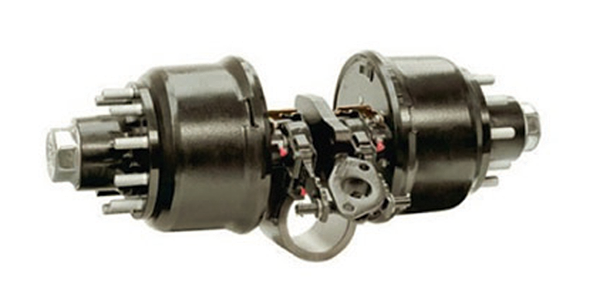

BPW SWING AXLES

Swing axles can absorb any unevenness on the road with a pendulum motion along the length and across the width of the vehicle. This makes them ideal for the most diffi cult road conditions in rough terrain. In the vehicle, they are arranged in pairs next to each other as an axle line. BPW swing axles are reliable and easy to maintain, incorporate space-saving technology from large-series production and off er a long life expectancy – making them the most cost-eff ective solution on the market. They are designed for use in extreme conditions and are primarily used in low loader trailers, special-purpose vehicles and modular platforms. These axles can also accommodate particularly heavy loads and have been designed with the dimensions to match: The BPW swing axle portfolio ranges from a 6 tonne axle load to the 9–12 tonne series and extends through to the extremely heavy-duty range. BPW off ers custom solutions for specifi c industrial applications starting from 13 tonnes and continuing right through to a 60-tonne axle load.