Photovoltaic modules are integrated into the roofs of these trucks.

Text: Oliver Schoenfeld

Photos: Fraunhofer ISE

The large roof surfaces of box bodies, with their attractive sunny position, are ideal for generating renewable energy. A Fraunhofer research team is therefore testing new concepts for vehicle-integrated photovoltaics.

Subsequent on-roof mounting or full integration

For electrified commercial vehicles, the starting conditions are particularly promising due to the high battery capacities. However, the extra boost of solar energy can also be worthwhile for commercial vehicles with combustion engines. In the course of the “Lade-PV” project funded by the German Federal Ministry of Economics, the Freiburg scientists are therefore developing lightweight and robust PV modules for two applications: retrofitting on the roof and full integration in the vehicle body.

»An installed capacity of eight gigawatts would be possible on truck roofs in Germany alone.«

Christoph Kutter, Project Manager Fraunhofer ISE

High energy yield with low weight

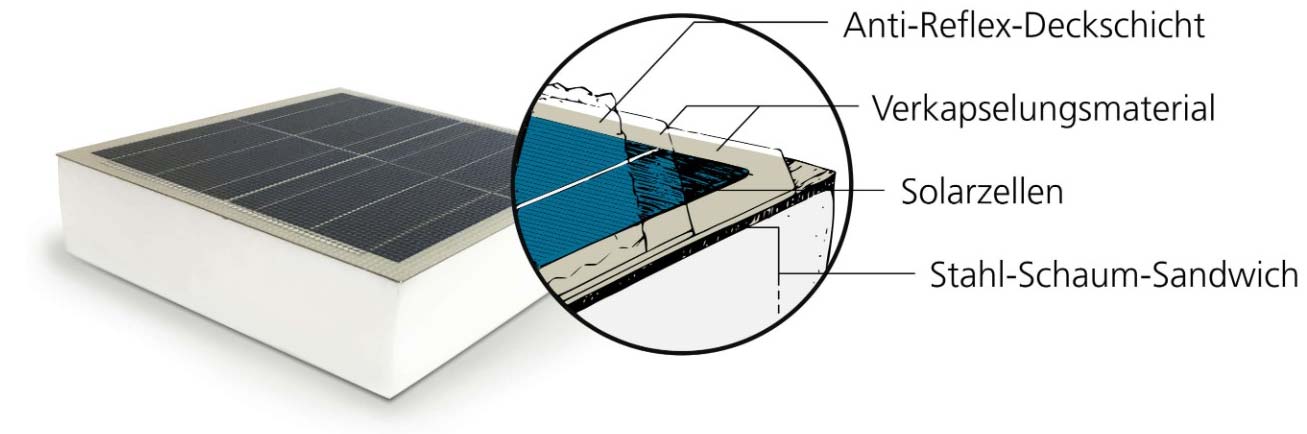

Schematic structure of a lightweight module for refrigerated box trucks