Text: Oliver Schönfeld

Photos: MGM Bulk

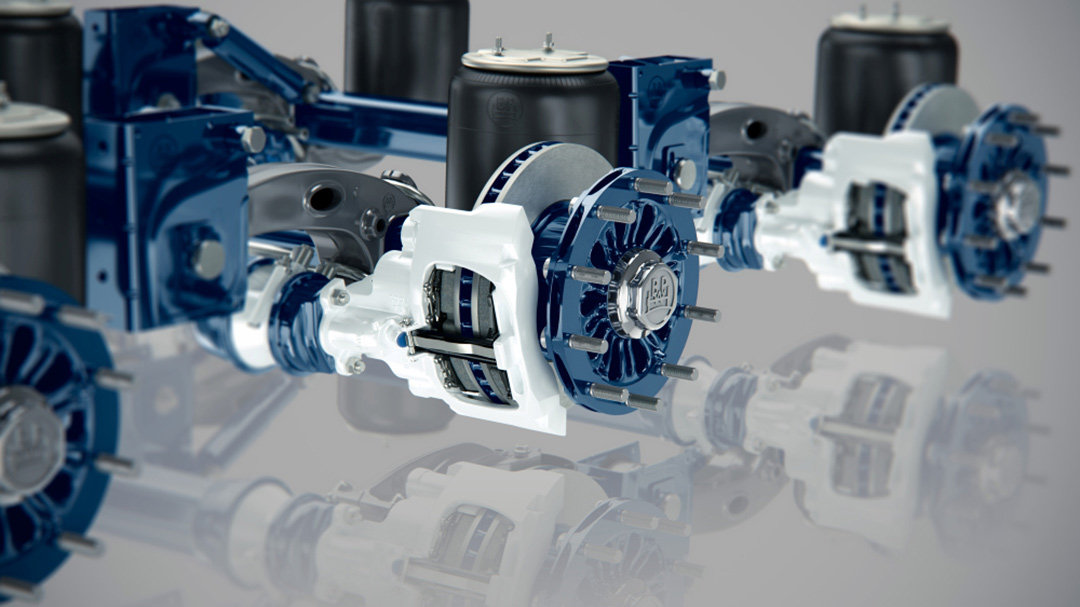

16 axles, a proud 32 metres in total length and a gross combination mass of 116 tonnes: The Roadtrain from MGM Bulk and Bruce Rock Engineering, which is used in mining in Australia, sets special standards.

Twelve months development time

»With the newly developed Roadtrain, we increase the maximum possible payload by almost 20 per cent.«

Damion Verhoogt, Managing Director Bruce Rock Engineering

More efficiency, less heavy goods traffic

Driving characteristics and driving dynamics improved

Relying on BPW components for decades

Family-run transport company for special requirements

With over 60 years of experience, 400 employees, a core fleet of 160 tractors and more than 550 trailers, the MGM Group is one of the leading transport companies in the state of Western Australia. It aims to help its clients provide safe and reliable logistics services – and in doing so, it is also constantly introducing innovations to the market. For example, MGM has been working on extra-long roadtrains and their advantages for productivity, cost efficiency and ecology for many years. In particular, the MGM Bulk division with bulk transports and the longer trailer trains has been recording above-average growth for several years. A large number of customers throughout Western Australia rely on the services of the family-run company – for bulk transport as well as for material handling.

“Mining in our region has been the focus of our family company’s work for decades,” Allan Thomas continues. In addition to these bulk goods transports the haulage company also works for limestone and quarry companies. According to Allan Thomas, three 32-metre Roadtrains are not the end yet: “If our customers have the necessary transport needs, more units of this type will certainly follow.