Reading time: approx. 4 minutes

Text: Oliver Schönfeld

Photos: Pia Simon

Manoeuvring on narrow farms and their even narrower access roads is an art in itself. With these special requirements in mind, trailer specialist Finkl has developed a new generation of vehicles for animal transport and uses the BPW Active Reverse Control auxiliary steering system. Customers from all over Europe are enthusiastic about the advantages.

The vehicle manufacturers of Josef Finkl KG from Bissingen in Bavaria have been dealing with the special requirements in the development of animal transporters for more than 40 years – and have thus built up a wealth of experience that makes the decisive difference from the customer’s point of view. After all, reliability and durability under demanding operating conditions are particularly important for the special trailers. In addition, numerous country-specific regulations and requirements regarding animal welfare have to be observed. With its strategy of specialisation, Finkl has made a name for itself as a quality supplier throughout Europe.

Durability and reliability are crucial

Since the mid-1980s, the company has relied on solutions from BPW Bergische Achsen KG. “Today, we only use axle systems from BPW,” emphasises Josef Finkl, the company’s third generation owner. “The high quality, the very good service and the ease of repair of the axles confirm us in this decision.” Especially for animal transporters, which are often in use for 15 years or more, durability and reliability are decisive purchase criteria. Josef Finkl explains: “A rule of thumb is that a trailer in this transport segment is used as long as three tractor units. Our Kombi-Liners and Low-Liners have to measure up to these high-quality expectations.”

»Auxiliary steering provides significant relief for the driver.«

Josef Finkl, owner and managing director of Josef Finkl KG

Facilitate manoeuvring when reversing

Steered trailers have been part of Finkl’s vehicle programme for many years. After all, space on farms and their access roads is often so limited that manoeuvring when reversing becomes a challenge every time. “Auxiliary steering offers considerable relief for the driver there,” explains Josef Finkl. In the past, the company has mainly worked with mechanical rod steering systems. Although this makes driving easier, it is still only a compromise – high assembly costs, high weight and a lot of service requirements during operation speak against this conventional solution

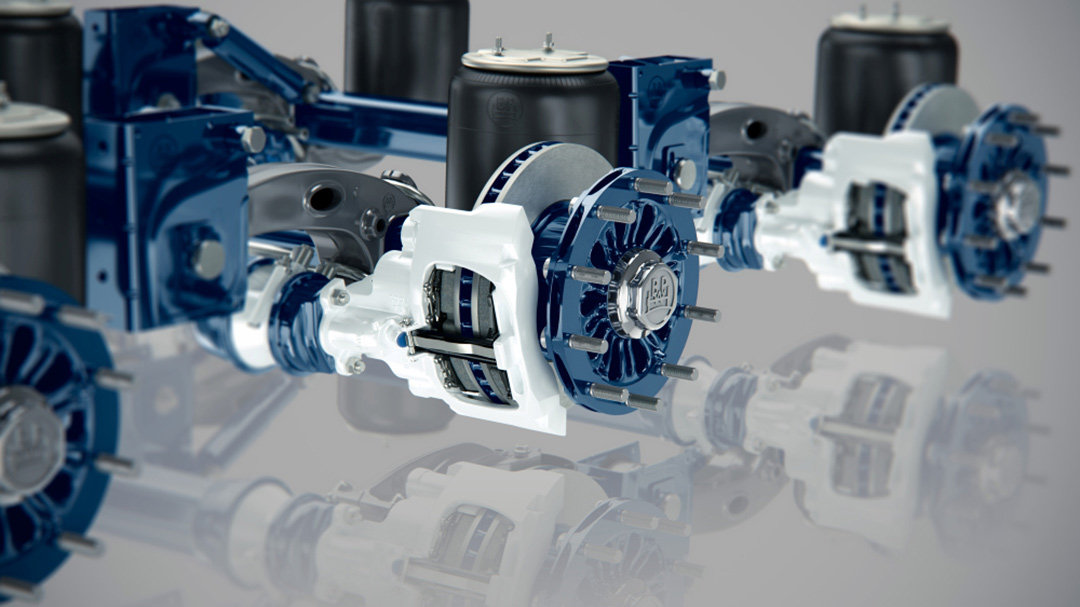

BPW Active Reverse Control: Auxiliary steering for safe manoeuvring

This made it all the quicker for Fahrzeugbau Finkl to decide to be one of the first users to work with the new variant of BPW Active Reverse Control (ARC). In addition to the familiar version for standard axles with 22.5″ single tyres, which is also used at Fahrzeugbau Finkl, the auxiliary steering in combination with the self-steering axle will soon also be available for low-loaders with 17.5″ twin tyres with SN 3020 drum brake. With a steering angle of 12 to 18 degrees, or up to 20 degrees for low-loaders, the additional steering makes manoeuvring considerably easier, and that with a particularly compact design. The series introduction of the low-loader version expands the auxiliary steering portfolio up to 12 tonnes axle load.

Better manoeuvrability proves its worth

The ARC has fully met the high expectations at Finkl. The first customers who have opted for the new generation of trailers praise the improved manoeuvrability in narrow access roads and yards and are pleased with the increased efficiency in daily vehicle operation. The compact and at the same time weight-saving design of the additional steering also brings a gain in efficiency. Denmark, for example, prescribes a minimum height of 98 centimetres per floor for animal transporters. “Due to the compact dimensions of the additional steering system compared to a rod steering system, the transport capacity increases significantly,” explains Josef Finkl. The simple installation according to the plug-and-play principle thanks to the factory-prepared axles as well as the pre-set software also convinced the Bavarian vehicle builders. Another advantage: ARC does not require approval. Since the trailers for animal transport have their own batteries, this is used to control the steering system. This makes the energy supply from the tractor unnecessary.

Training for the drivers

The transport companies from Germany, France and the Netherlands, which already have a Finkl trailer with ARC in use, are enthusiastic. The advantages in daily handling speak for themselves. Only the reverse manoeuvring with assistance requires some getting used to, Josef Finkl admits. “If possible, we usually train our customers’ drivers directly on this when they pick up the trailers from us.” But then they quickly get to grips with the additional steering and the remote control. “And afterwards the advantages, from time savings to less tyre wear, speak for themselves.”

Vehicle construction for over 80 years

Passion for vehicle construction has shaped the company development at Finkl for over 80 years. The grandfather of the current owner founded a blacksmith’s and wagon smithy in the market town of Bissingen in 1938. Since 1949, the company has been manufacturing at its current location on the outskirts of Bissingen. Several times over the decades, most recently in 2006, the assembly halls and the paint shop were expanded. Today, 90 highly qualified employees – from vehicle builders to painters and technicians – are employed at the company’s main site. In 2007, a second production facility was added in Roggendorf near Schwerin with currently 45 employees.

Specialisation as a concept for success

After the beginnings with the production of farm wagons and horse transporters, tipping trailers and tipping semi-trailers for the construction industry formed a second mainstay at the end of the 1960s. A particular focus was the production of special vehicles for the extensive construction activities in the run-up to the 1972 Olympic Games in Munich. In the mid-1980s, the company decided to take the next step in specialisation. Since then, the focus has been solely on the development and construction of vehicles for animal transport. “We know our customers’ requirements and find solutions in strict compliance with legislation that places a high value on animal welfare,” emphasises owner Josef Finkl.