Text and photos: Oliver Schönfeld

Mustafa Celik does not take heavy loads lightly: The haulage contractor has specialised in demanding coil transports for many years and finds solutions for his clients even when others turn away.

Every kilogram counts in lightweight construction

Technology always in view via telematics

»For a long time I have wanted a solution that not only controls tire pressure, but can also pump it up when needed.«

Mustafa Celik, Managing Director M. Celik Transport GmbH

Already prevented several punctures

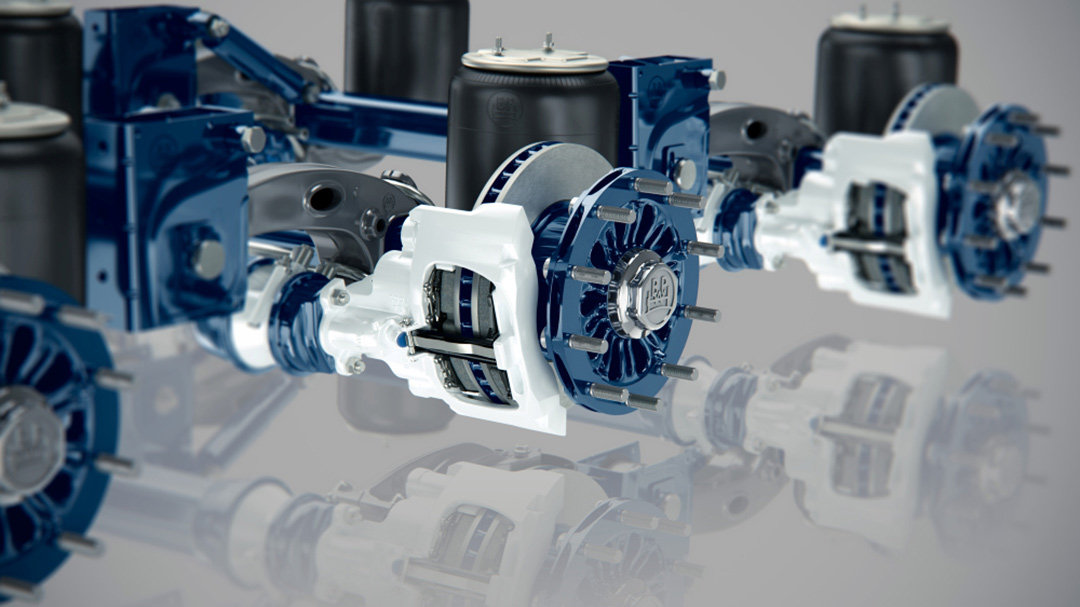

The tire pressure is constantly monitored and automatically adjusted to the desired pressure via a control box with booster. Because the pressure is optimally set at all times, Celik permanently saves fuel and reduces CO 2emissions. According to BPW’s calculations, the cost benefits add up to more than 700 euros per year for a three-axle vehicle with an annual mileage of 120,000 kilometres and an average pressure deviation of ten percent. This does not include the savings in time, nerves, vehicle and delivery downtime. In the event of major deviations in pressure, for example in the event of a defect, the system issues a warning.

The trailers equipped with AirSave have been in daily operation at Celik for a good year and a half. “Twice already, we were able to bring the vehicle safely to its destination despite an impending tyre problem because the system continuously readjusted the air pressure,” says Mustafa Celik. Without AirSave, there would have been the threat of an unplanned vehicle standstill, including a cost-intensive tyre replacement en route. The advantages are convincing: Celik is also having the next new order of 15 trailers in 2022 equipped with the system.