Reading time approx. 4 minutes

Text: Oliver Willms

Photos: Richard Kienberger, SCHERM Gruppe

The logistics experts of Bavaria’s SCHERM Group are deploying the first-ever 40-tonne truck with electric drive for just-in-time deliveries for BMW. This is a clear push towards alternative drives for trucks.

A gentle whirring – this is the sound with which system provider SCHERM heralds the future of truck deliveries. It is the running noise of the 188 hp electric motor that can get a 40-tonne truck off to a start that is as quick as it is quiet. This way, the logistics experts from Upper Bavaria are operating the automotive sector’s first fully fledged articulated truck to work 100 percent CO2-free.

“We have been looking for a transport solution like this for a long time,” explains Daniel Pasztor, Managing Director of SCHERM Logline Transport GmbH. For the family company, sustainability is more than just a trend to keep up with. On the contrary, environmental compatibility has long been the watchword in every area of the firm. This ecological commitment manifests itself in many ways, from electric drives for small vehicles and industrial trucks to the latest emission control technology for trucks, the use of more efficient long trucks, and the company’s own photovoltaic system.

Perfect partner

Utilising fully electric trucks was thus a logical step, if not entirely straightforward to implement. “A few years back, we put a lot of thought into possible alternatives for diesel engines in local transport,” explains Daniel Pasztor. The right supplier was found in the form of Dutch special vehicle manufacturer Terberg. Based on a terminal tractor, the first fully electric semi-trailer tractor was designed that is able to pull a 40-tonne combination on public roads as well.

At the other end of the supply chain, BMW is the perfect partner for CO2-free driving in the streets of Munich: a vehicle manufacturer that also invests a great deal of (electric) energy in sustainable mobility. And thus, eight times a day, the gently whirring SCHERM E-truck makes its way from the supply centre to the main BMW plant in Milbertshofen in the north of the Bavarian capital, just three kilometres away. That is where the barely audible, electricity-powered traction unit with its low-deck trailer delivers vehicle components such as shock absorbers, steering boxes or suspension springs to the production line, just in time.

Charged with green electricity

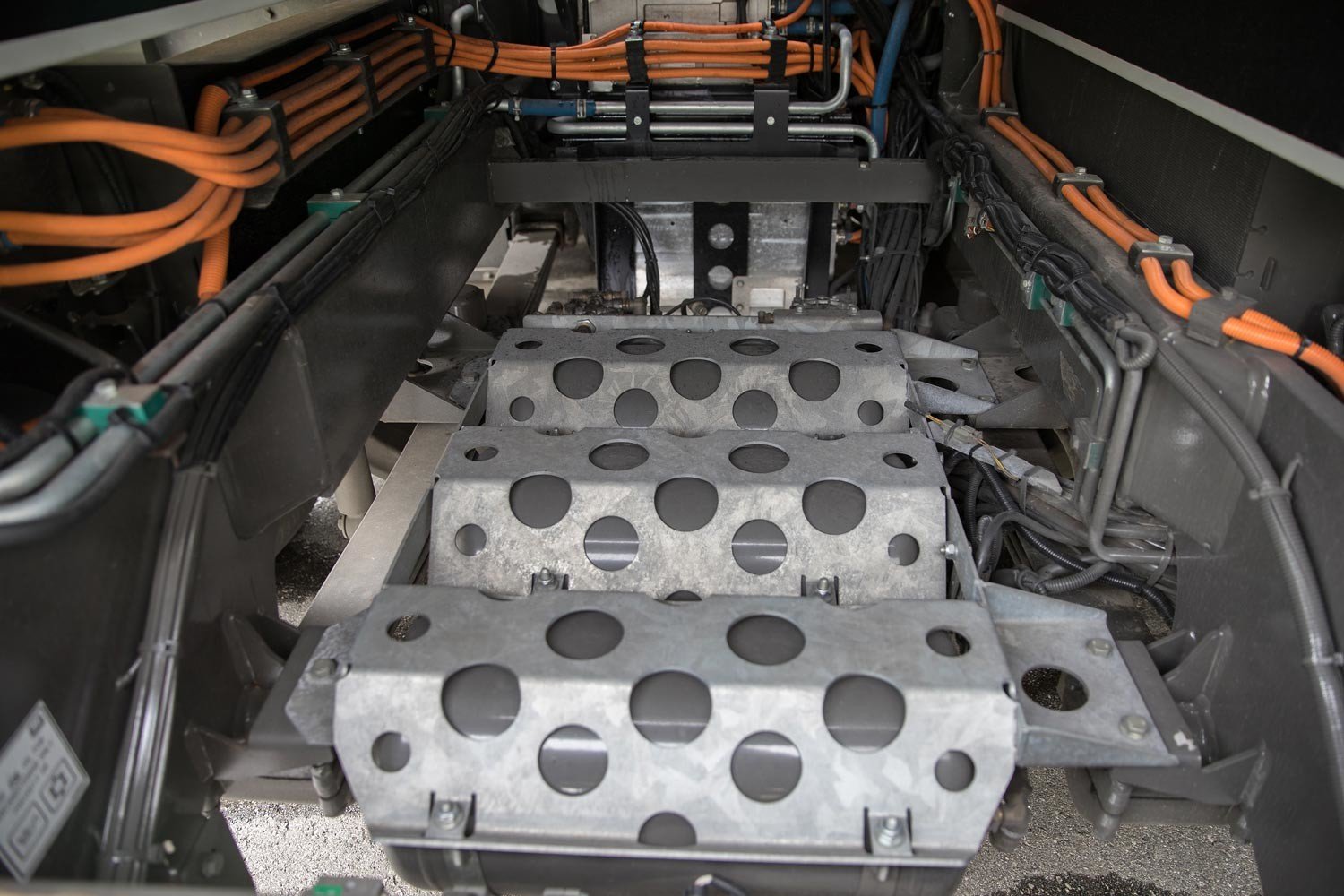

The E-truck can manage 100 kilometres with a single charge of its two lithium-ion batteries. When power runs low, the agile Terberg heads back to park next to an oversized socket at the charging station in the SCHERM depot. Three to four hours later, it is recharged to full capacity – naturally with green electricity.

Even with a full load, the system performance of 132 kilowatts delivered to the four-speed automatic transmission by the Siemens asynchronous engine is entirely sufficient for the shuttle service between the logistics warehouse and the BMW plant. Regular driver Christoph Michalski has become enamoured with his vehicle: “I now prefer the electric truck to driving a normal truck,” he says. Nothing is lacking in the compact cab of the traction unit, there is an impeccable view of the surroundings, and the steps on the side make it easy to climb into the cab.

Only the relatively high unladen weight of ten tonnes – two of which are due to the batteries alone – indicates that these Terberg tractors are normally at work for many years in the harsh environment of container and terminal handling. Like every other electric truck driver, Michalski has undergone special training on how to deal with the vehicle. “We set very great store by safety,” says Daniel Pasztor. “We won’t compromise on that score!” To prove this point, the heavy vehicles in the SCHERM fleet are fully equipped with safety components such as vehicle-interval radars and lane guidance assistants.

Daniel Pasztor, Managing Director of SCHERM Logline Transport, is very satisfied with his sustainable form of city transport.

Proven in practice

As stipulated by regulations, electric trucks are limited to a maximum speed of 40 kilometres per hour. However, this is of negligible impact in city traffic, whereas the maximum torque – typical for electric engines – is immediately available. After more than a year of practical use, the electric articulated truck has proven itself as a thoroughly reliable partner: there were no significant failures or downtimes, either in winter or in summer. Throughout, the vehicle fulfils the comparatively high sustainability requirements of both SCHERM and its partner and customer BMW. The response to the successful trial has been great, reports marketing director Maximilian Roos: “We have had an enormous amount of feedback and positive reactions throughout!”

High acquisition cost

In terms of image and environmental protection, the trial can thus be considered a genuine hit. Only the financial aspects are not yet satisfactory, despite lower fuel costs compared to diesel. “The acquisition cost for this vehicle is about three times as much as that for a conventional truck,” calculates Daniel Pasztor. “It would be inappropriate, however, to view the deployment from a purely financial perspective.” Incentives such as government funding would be needed to achieve profitability.

Despite this, the deployment of the first electric truck has been a complete success for SCHERM. Pasztor is convinced: “Together with our partners, we are demonstrating that practical application is both feasible and reliable!” As can be seen elsewhere in the burgeoning field of electromobility, larger quantities are needed for the technology to become economically viable. Sustainability pioneers such as SCHERM are important trendsetters enabling the utopia of gentle whirring to turn into a real-life orchestra of electric commercial vehicles.

SCHERM Group

The SCHERM Group emerged in 1972 from an agricultural trade business in Karlskron near Ingolstadt, and has since developed into an international system provider with 14 locations and around 2,000 employees. Today, the family-run company is active in the areas of logistics, transport, property and services. The automotive division serves a variety of vehicle manufacturers, including Upper Bavarian neighbours BMW and Audi. SCHERM operates its own fleet of around 500 transport vehicles. Modern, environmentally sound technology and maximum safety are key objectives of the company philosophy.